Dedicated Local Private Networks Powering the Factory of the Future

The landscape of modern manufacturing is changing rapidly with the emergence of Industry 4.0. Gone are the days when factories relied solely on isolated machines or old-school IT setups; now, they’re evolving into digitally interconnected ecosystems, driven by sensors, IIoT devices, automation tools, and advanced analytics.

To really make this vision a reality, a solid, secure, and highly reliable communication infrastructure is crucial. Standard public cellular networks or Wi-Fi just can't keep up with the intense demands of automation. That’s where dedicated local private networks come in, helping ensure that the factory of the future runs smoothly.

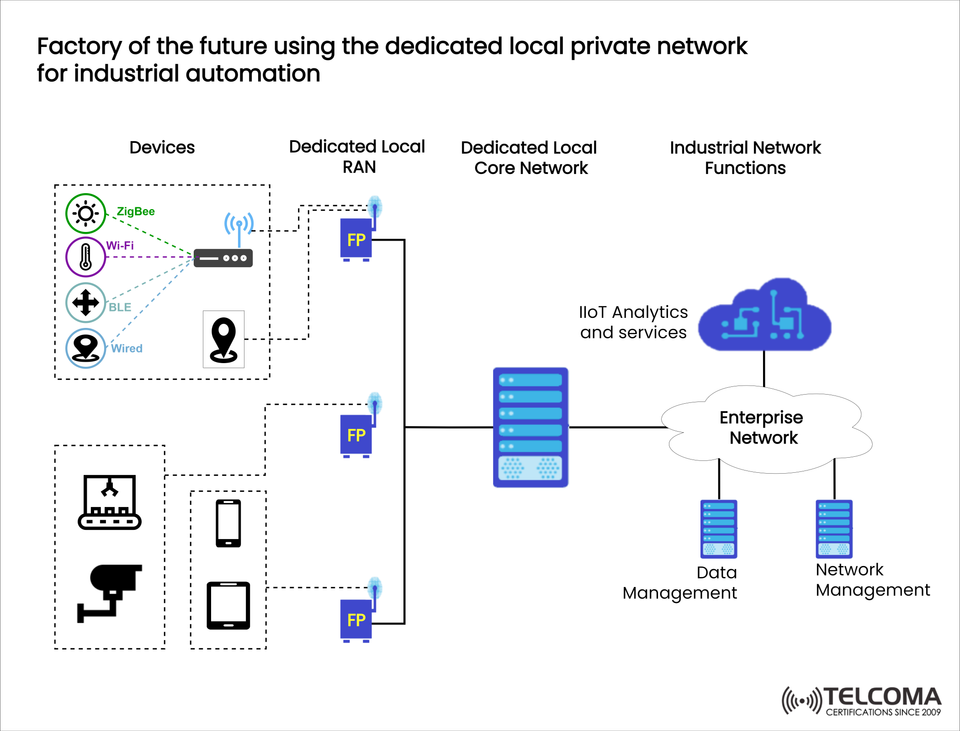

The image provided clearly shows how a private network fits together with devices, dedicated local RAN, a local core network, and enterprise-level functions like IIoT analytics, data management, and network management.

What is a Dedicated Local Private Network?

A dedicated local private network is a tailored communication system created just for a specific enterprise or industrial site. Unlike public cellular networks, this is built and operated right where the enterprise is, providing:

Reliable quality of service (QoS) with minimal interference.

On-premises data processing, which keeps things secure and private.

Ultra-reliable low latency communication (URLLC), essential for robotics and automation.

Scalability, allowing for thousands of connected devices at once.

This makes private networks a fundamental part of industrial automation and a key step toward Industry 4.0.

Breaking Down the Architecture

The image showcases the end-to-end architecture of a smart factory supported by a private network. Here’s a closer look at each component:

- Devices Layer

This layer consists of the various endpoints found throughout a factory:

Industrial sensors that track temperature, vibration, and other environmental factors.

Robotics and actuators used in automated manufacturing processes.

Cameras for surveillance, quality control, and detecting anomalies.

Mobile devices like smartphones and tablets for operator interactions.

These devices connect through various methods:

ZigBee: A low-power, short-range wireless technology for sensor communication.

Wi-Fi: High-speed, local connections for demanding applications.

BLE (Bluetooth Low Energy): Energy-efficient communication for IoT tags and wearables.

Wired connections: Essential for mission-critical applications that require ultra-reliable connections.

- Dedicated Local RAN (Radio Access Network)

The RAN is how devices connect to the private network. In a factory setting, this often involves 5G small cells, Wi-Fi access points, or a mixed solution.

Its functions include:

Offering coverage across the factory space.

Ensuring low-latency access for devices.

Supporting mobility management, so connected robots or AGVs (Automated Guided Vehicles) can move around freely without losing their connection.

- Dedicated Local Core Network

The core plays a key role in managing data flow from the RAN, ensuring everything runs securely and efficiently. It handles:

Device authentication and authorization.

Routing and switching of industrial traffic.

Policy enforcement that prioritizes critical applications.

Local data management, ensuring that sensitive information stays within enterprise borders.

- Industrial Network Functions

The private network connects effortlessly with enterprise systems and IIoT analytics platforms.

IIoT Analytics and Services: Real-time analysis of data streams from machines, sensors, and cameras.

Enterprise Network Integration: Links Operational Technology (OT) with Information Technology (IT).

Data Management: Handles large amounts of structured and unstructured data.

Network Management: Includes monitoring, troubleshooting, and optimizing network performance.

Benefits of Dedicated Local Private Networks in Factories

Setting up private networks for industrial automation offers a range of strategic advantages:

Ultra-Reliable Connectivity: Essential for robotics and automation.

Better Security: Keeping data on-premises reduces the risk of external threats.

Low Latency: Allows for real-time monitoring and control.

Huge Scalability: Supports thousands of devices without a hitch.

Operational Efficiency: Boosts uptime and cuts down costly downtimes.

Seamless Integration: Unifies multiple connectivity technologies under one core.

Use Cases in Industrial Automation

Predictive Maintenance

Sensors keep an eye on machine health continually.

Data analytics spot potential failures before they occur, reducing downtime.

Smart Surveillance & Safety

High-definition cameras identify anomalies in real-time.

AI can flag safety risks or intrusions.

Autonomous Robotics

Robots and AGVs sync their operations wirelessly.

Guarantees precise and coordinated movements on assembly lines.

Real-Time Asset Tracking

BLE and RFID tags monitor tools, equipment, and products.

Enhances visibility and efficiency in the supply chain.

Augmented & Virtual Reality Applications

Technicians can use AR glasses or tablets for real-time help.

Improves training, maintenance, and troubleshooting efforts.

Comparison: Public vs Private Networks for Factories

Feature | Public Networks | Dedicated Private Networks

Reliability | Shared, prone to congestion | Enterprise-controlled, highly reliable

Latency | Variable (20–50 ms typical) | Ultra-low (1–10 ms)

Security | Data leaves enterprise boundary | On-premises, enterprise-owned

Customization | Limited | Highly customizable policies

Device Support | General-purpose | Tailored to IoT/IIoT scalability

The Role of 5G in Private Industrial Networks

The implementation of 5G technology significantly enhances the capabilities of private networks in factories:

URLLC (Ultra-Reliable Low Latency Communication): Facilitates real-time control of robots and machinery.

mMTC (Massive Machine-Type Communication): Connects thousands of IIoT sensors at once.

Network Slicing: Allows for dedicated network slices tailored for specific industrial needs.

Edge Computing Integration: Brings computation closer to the devices, further lowering latency.

Private networks powered by 5G lay the groundwork for fully automated smart factories.

Challenges in Deployment

Even with their numerous benefits, private networks do face some challenges:

High Initial Costs: Setting up the infrastructure takes investment.

Spectrum Licensing: Getting access to dedicated spectrum varies with local regulations.

Skill Shortage: Companies might lack the know-how to manage telecom-grade networks.

Integration Complexity: Connecting IT and OT environments needs careful planning.

That said, partnerships with telecom operators and managed service providers are helping businesses tackle these challenges.

Conclusion

The image effectively showcases how the factory of the future utilizes a dedicated local private network for industrial automation. By integrating devices, local RAN, a private core, and enterprise-level analytics, these networks deliver the low latency, high reliability, and security needed for Industry 4.0.

From predictive maintenance and robotics to real-time analytics and AR applications, dedicated private networks lay the foundation for the next generation of factories. With the added advantages of 5G and edge computing, businesses are well on their way to creating smarter, safer, and more efficient industrial environments.

The future of manufacturing is connected, intelligent, and driven by private networks—a crucial step toward realizing the full potential of industrial automation.