Digital Twins in Industrial Environments: Architecture, Layers, and Real-Time Data Synchronization

Digital Twins in Industrial Settings: Connecting the Physical and Digital Realms

The advent of Industry 4.0 has brought in breakthrough technologies that connect physical systems with digital intelligence. At the heart of this change is the Digital Twin (DT) — a virtual model of physical assets that allows for real-time tracking, predictive analytics, and automated decision-making.

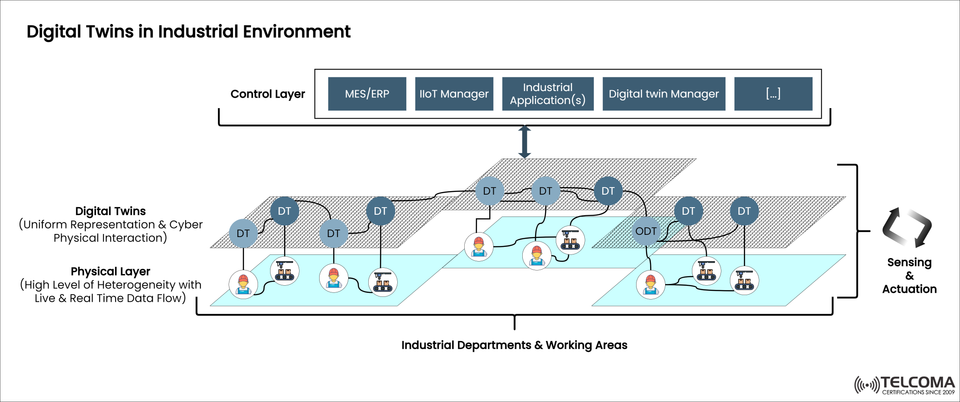

The illustration provided by Telcoma demonstrates the Digital Twin framework in an industrial setting, highlighting how control systems, digital twins, and physical assets interact within a cohesive data ecosystem. This structure not only enhances operational visibility and performance but also fosters cyber-physical integration — which is essential for achieving the smart factory of the future.

Grasping the Digital Twin Concept

A Digital Twin (DT) acts like a virtual reflection of a real-world entity — think machines, production lines, or even a human operator. It continuously gathers data from sensors installed in the physical object, which enables:

Real-time performance tracking

Predictive maintenance

Simulation and optimization

Autonomous control actions

In industrial settings, DTs function as the nervous system of connected factories, linking IoT devices, AI algorithms, and enterprise software systems for streamlined control and analysis.

Architecture Overview

The diagram illustrates how Digital Twins function within a multi-layered industrial environment, merging different systems and data streams.

The architecture has three main layers:

Control Layer

Digital Twin Layer

Physical Layer

These layers communicate through ongoing sensing, data synchronization, and actuation, creating a closed-loop system for smart operations.

Control Layer: The Hub of Industrial Intelligence

At the top of the architecture is the Control Layer, where enterprise and operational systems come together to manage industrial processes.

Components:

MES/ERP: Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) handle production schedules, inventory, and resource distribution.

IIoT Manager: Oversees connected IoT devices, sensors, and gateways that gather real-time operational data.

Industrial Applications: Deal with specialized functions like process optimization, analytics, and visualization.

Digital Twin Manager: Manages the lifecycle of all digital twins — from their creation and synchronization to analysis.

This layer serves as the brain of the system, offering global oversight, coordination, and decision-making abilities.

Digital Twin Layer: The Cyber-Physical Connection

The Digital Twin Layer acts as the link between the physical realm and control systems. It serves as a single digital mirror for all industrial assets, processes, and operators.

Key Traits:

Uniform Representation: Each machine, operator, and sensor has a corresponding DT, ensuring consistent modeling across departments.

Cyber-Physical Interaction: DTs exchange information with their physical counterparts through IoT and sensor networks.

Interconnected Twins: DTs can communicate with each other to simulate entire workflows, not just isolated components.

For example, the diagram shows several DTs interacting across different industrial zones — machines, workers, and robots — all represented in the digital layer for smooth system coordination.

Benefits:

Increased visibility into production status.

Simulation-driven optimization before making physical changes.

Fault detection and predictive maintenance.

Physical Layer: Real-Time Operations and Sensing

The Physical Layer encapsulates the real-world environment, which includes:

Machines and robots completing tasks.

Human operators engaged in production lines.

Sensors and IoT devices gathering operational data.

This layer is marked by heterogeneity — a mix of devices, communication protocols, and data types coexisting within a single ecosystem.

Core Features:

Live & Real-Time Data Flow: Continuous streams of sensor data feed into DTs for immediate analysis.

High Level of Heterogeneity: Integrates various machinery, from older industrial setups to new IoT-enabled devices.

Edge Sensing & Actuation: Real-time data is processed on-site for ultra-fast response and control actions.

Data Flow and Synchronization

A crucial part of Digital Twin systems is ensuring real-time synchronization between the physical and digital entities.

The cycle flows through:

Sensing: Physical assets relay telemetry and environmental data via sensors.

Transmission: Data moves to the DT layer using industrial networks (like Ethernet, 5G, or IIoT).

Processing: DTs analyze incoming data for valuable insights.

Actuation: Control commands are sent back to physical systems to adjust their behavior (like temperature control or motor speed).

This sensing–actuation loop guarantees that digital and physical systems evolve together — always aligned and responsive.

The Importance of Communication and Network Infrastructure

Telecommunication networks, especially 5G and edge computing, are crucial in supporting digital twin ecosystems.

Key Network Facilitators:

Low Latency: Vital for real-time control and feedback loops.

High Bandwidth: Necessary for sending large amounts of telemetry data.

Edge Computing: Processes data close to where it’s generated, reducing the need for backhaul.

Network Slicing: Allocates dedicated network resources for various industrial tasks (like control versus monitoring).

In essence, telecom infrastructure acts as the connective backbone, allowing digital and physical environments to function seamlessly together.

Cross-Industry Integration

The diagram shows different working zones and departments, each with its own DTs tied into the same digital ecosystem.

Cross-Departmental Advantages:

Unified Data View: DTs consolidate insights from all areas for centralized analysis.

Collaborative Decision-Making: Maintenance, operations, and management can jointly make decisions based on shared digital models.

Process Standardization: Ensures steady performance and interoperability across facilities and regions.

This level of integration allows for scalable industrial automation, enabling organizations to grow without sacrificing synchronization or visibility.

Benefits of Implementing Digital Twins

a. Operational Efficiency

Automates data analysis and control loops for quicker response times.

b. Predictive Maintenance

Spots anomalies ahead of failures, prolonging asset longevity.

c. Cost Optimization

Cuts down on unexpected downtime and energy usage.

d. Improved Collaboration

Bridges communication gaps between various departments and control systems.

e. Enhanced Safety

Monitors operator conditions and environmental risks in real time.

Challenges and Considerations

While integrating Digital Twins holds significant promise, it also brings about technical and organizational hurdles:

Data Security: Constant data exchange calls for strong cybersecurity measures.

Standardization: The absence of universal data formats complicates interoperability.

Scalability: Managing numerous interconnected twins demands powerful infrastructure.

Skill Gaps: Training in data-driven methods is essential for operators and engineers.

Future solutions will likely include AI-driven orchestration, 6G communication, and autonomous DT agents to tackle these challenges.

The Future of Digital Twins in Industrial Transformation

As industries transition toward Industry 5.0, Digital Twins will be essential in merging human intelligence with machine automation.

AI-powered self-learning twins will autonomously adapt and predict.

Cognitive DTs will model human behavior for safety and ergonomics.

Blockchain-based DT ecosystems will secure data exchange across organizations.

Ultimately, DTs will lay the groundwork for adaptive, self-optimizing industrial networks.

Conclusion

The introduction of Digital Twins in industrial settings signifies a major shift from static automation to dynamic, data-driven collaboration.

As illustrated in the diagram, integrating control systems, digital models, and physical assets creates a closed-loop ecosystem, where data continuously drives enhancement. By merging telecommunication technologies, IIoT, and AI, industries can achieve real-time intelligence, adaptive production, and a blend of human-machine collaboration — paving the way for the smart factories of tomorrow.