Factory of the Future with Dedicated Local Private Networks for Industrial Automation

Introduction

The fast-paced evolution of Industry 4.0 has changed the game for factories. With needs ranging from real-time monitoring to predictive maintenance, industries are on the lookout for solid, secure, and quick connectivity options. Traditional public networks often can't keep up, falling short with congestion, inconsistent performance, and limited control.

This is where dedicated local private networks step in as a game-changer for industrial automation.

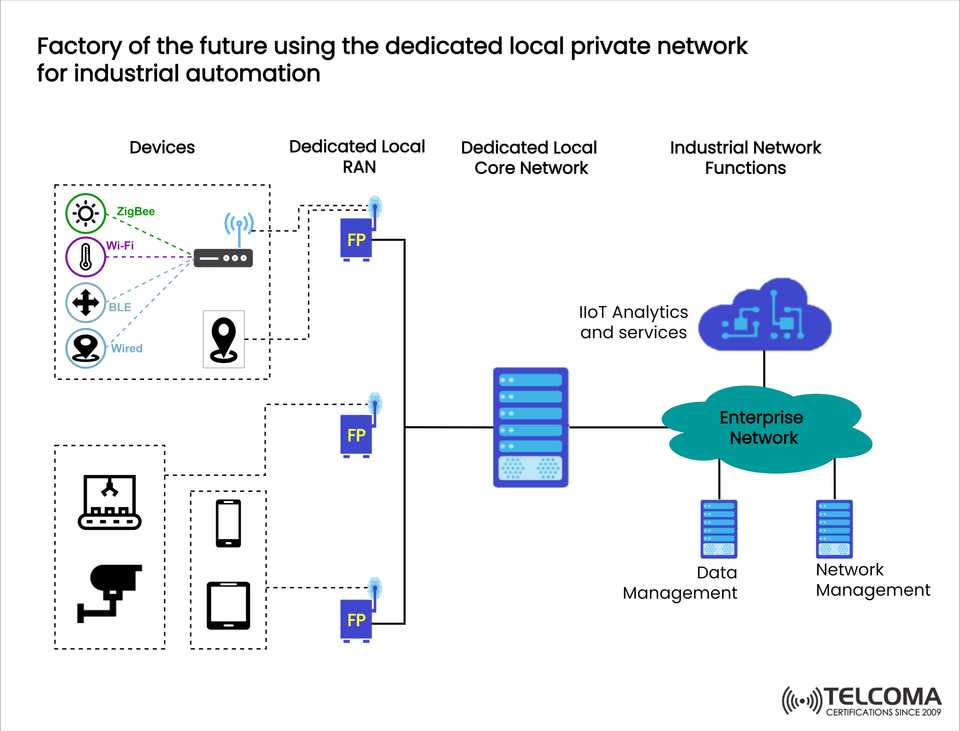

The diagram included shows how factory devices connect through a dedicated local RAN (Radio Access Network) and a core network. This setup allows for IIoT (Industrial Internet of Things) analytics, data management, and enterprise services. It seamlessly links operational technologies (OT) with enterprise IT systems, paving the way for the factory of the future.

What is a Dedicated Local Private Network?

A dedicated local private network is a communication system designed specifically for an enterprise or industrial setting. Unlike public cellular networks, it offers:

Exclusive spectrum allocation or shared spectrum use with specific QoS (Quality of Service) settings.

Complete control over network resources to ensure security and reliability.

On-premises infrastructure that lessens dependency on outside operators.

Ultra-reliable low latency communication (URLLC), which is key for automation and robotics.

This type of network is the backbone of industrial automation because downtime or poor connectivity can lead to costly production delays.

Architecture of the Factory of the Future

The image depicts a four-layer structure for the dedicated local private network aimed at industrial automation:

- Devices Layer

Covers various factory devices:

Sensors (like temperature, motion, and vibration).

Industrial robots and actuators.

Cameras for monitoring and quality checks.

Smartphones and tablets for operator interfaces.

Communication happens through several technologies:

ZigBee for low-power sensor communication.

Wi-Fi for high-throughput local connections.

BLE (Bluetooth Low Energy) for energy-efficient short-range data transfer.

Wired connections for critical, latency-sensitive operations.

- Dedicated Local RAN

Serves as the access layer connecting devices to the private network.

Utilizes small cells, access points, or local 5G radios.

Guarantees coverage within the industrial site, while maintaining controlled latency and bandwidth.

- Dedicated Local Core Network

Manages and directs traffic from the RAN.

Offers features like authentication, mobility management, and security.

Keeps data within enterprise boundaries, boosting privacy and control.

- Industrial Network Functions & Enterprise Network

Connects with higher-level services:

IIoT Analytics and Services: Processes data for predictive maintenance, anomaly detection, and real-time optimization.

Data Management: Safely handles large volumes of industrial data.

Network Management: Monitors performance and handles faults.

Enterprise IT Integration: Links OT (Operational Technology) with IT systems for well-rounded decision-making.

Why Dedicated Private Networks are Key to Industrial Automation

Utilizing a dedicated local private network in factories comes with significant advantages:

High Reliability: Guarantees uptime for consistent production.

Low Latency: Supports real-time control for robotics and automation.

Enhanced Security: Keeps sensitive industrial data safely within enterprise boundaries.

Scalability: Capable of supporting thousands of IoT devices with various connectivity needs.

Flexibility: Integrates multiple access technologies (ZigBee, Wi-Fi, BLE, wired).

Cost Efficiency: Reduces downtime and enhances operational efficiency through predictive analytics.

Industrial Automation Use Cases Enabled by Private Networks

Predictive Maintenance

Continuous monitoring of machine health using sensors.

AI-driven analytics catch anomalies before they lead to breakdowns.

Autonomous Robotics

Robots communicate wirelessly with ultra-low latency.

Facilitates safe and efficient teamwork with human operators.

Smart Surveillance & Safety

High-definition cameras keep an eye on production lines.

AI identifies safety risks in real time.

Real-Time Inventory Tracking

BLE and RFID tags follow goods around the facility.

Links to enterprise resource planning (ERP) systems streamline supply chains.

Augmented Reality (AR) for Workforce

Tablets and AR glasses offer real-time support to technicians.

Enhances training, troubleshooting, and assembly accuracy.

Comparison: Public Networks vs Dedicated Local Private Networks

Feature Public Network Dedicated Private Network Reliability Shared, unpredictable Guaranteed, enterprise-controlled Latency Variable Ultra-low, optimized for automation Security Shared infrastructure risks Localized, enterprise-only data flow Scalability Limited customization Tailored to factory needs Control Managed by operators Fully managed by enterprise

The Role of I IoT Analytics in the Factory of the Future

One key component shown in the diagram is I IoT analytics and services. Once devices and sensors channel data into the enterprise network, analytics platforms reveal valuable insights:

Operational Efficiency: Spots process bottlenecks.

Energy Management: Optimizes energy usage.

Quality Control: Identifies defects in real time, cutting down waste.

Worker Safety: Predicts potential hazards to avoid accidents.

By combining analytics with the private network setup, factories are getting closer to autonomous, self-optimizing operations.

Challenges in Deploying Dedicated Local Private Networks

Although private networks provide transformative benefits, they do come with challenges:

Deployment Costs: Initial setup of private RAN and core infrastructure can be high.

Spectrum Licensing: Companies may need regulatory approval.

Integration Complexity: Merging OT systems with IT infrastructure can be tricky.

Skill Gaps: There's a need for workforce training in telecom-grade networking.

Telecom operators and vendors are tackling these issues by offering managed private network solutions, which include deployment, operation, and lifecycle support.

How 5G Strengthens the Factory of the Future

Integrating 5G with private networks speeds up industrial automation:

URLLC (Ultra-Reliable Low-Latency Communication): Guarantees instant responsiveness.

Massive Machine-Type Communication (mMTC): Supports a vast number of connected devices.

Network Slicing: Dedicates specific resources for crucial industrial applications.

Edge Computing Integration: Brings computation closer to the factory, further minimizing latency.

This combination of 5G and dedicated local private networks lays the groundwork for Industry 4.0 and beyond.

Conclusion

The image clearly shows how the factory of the future utilizes a dedicated local private network for industrial automation. By bringing together sensors, industrial devices, and IIoT analytics within a dedicated RAN and core network, companies can achieve remarkable reliability, control, and efficiency.

From predictive maintenance to autonomous robotics, private networks are reshaping industry operations. Even though there are challenges, advancements in 5G and managed services are making it easier to adopt this technology.

The future of manufacturing hinges on secure, dedicated private connectivity—the foundation for smarter, safer, and more efficient factories.