Industrial Collaboration through Digital Twins: Human-to-Machine Interaction in Smart Manufacturing

Working Together: Operators and Machines with Digital Twins

The fourth industrial revolution (Industry 4.0) is changing the way people and machines interact. We're moving away from isolated automation and starting to build collaborative ecosystems where operators, machines, and control systems can share data in real-time. At the core of this change is the Digital Twin (DT)—a virtual model that reflects how a physical asset or process behaves, performs, and what state it's in.

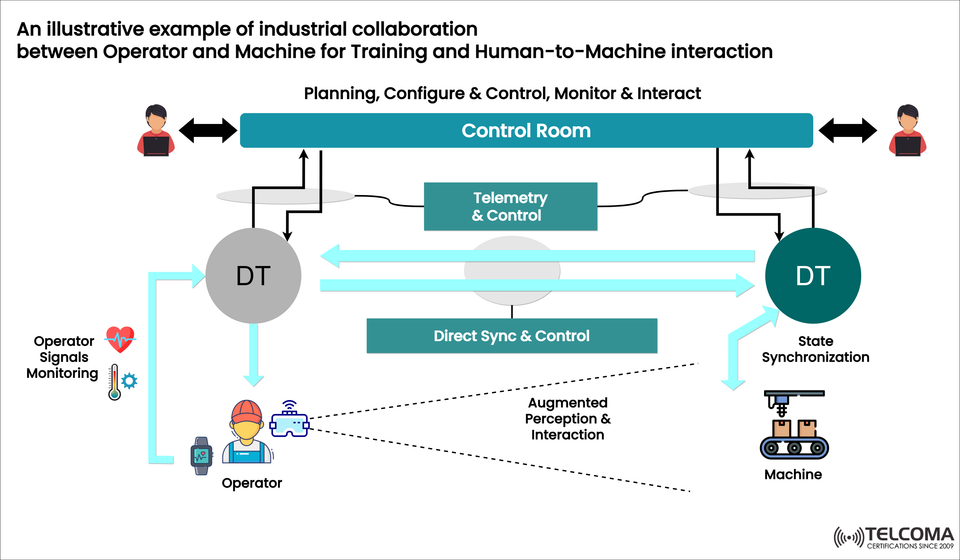

The diagram shared (by Telcoma) shows how industrial collaboration unfolds between the operator and the machine through Digital Twin technology, AI-driven telemetry, and augmented perception systems. This tech integration boosts training, safety, and operational efficiency, while also keeping the physical and digital worlds in sync.

What Human-to-Machine Collaboration Looks Like

In a connected industrial setting, human-to-machine (H2M) collaboration goes beyond just automation. It involves two-way communication, real-time decision support, and digital augmentation that helps operators make better-informed choices.

Key Elements of Collaboration:

Monitoring Operator Signals: Gathers biometric and environmental data like heart rate, body temp, and stress levels.

Digital Twins (DTs): Create digital versions of both the operator and the machine, allowing smooth interactions and state synchronization.

Control Room: Functions as the central hub for monitoring, configuration, and decision-making.

Telemetry and Control: Manages data flow and remote control.

Direct Sync and Control: Allows for instant synchronization between physical machines and their digital twins.

These components work together to keep operators, control rooms, and machines connected and responsive to real-time changes.

Digital Twins (DTs) Explained

A Digital Twin serves as a virtual replica of a physical object, process, or system. In industrial applications, DTs can:

Simulate how machines operate.

Predict when performance might decline.

Enable remote monitoring and control.

Sync operational states between the digital and physical realms.

In the diagram:

One Digital Twin represents the operator, showing physiological and cognitive states.

A second Digital Twin represents the machine, capturing its operational conditions and performance data.

The interaction among these DTs, overseen by the control room and connected networks, facilitates real-time decision support and adaptive control.

Analyzing the Architecture

The diagram brings attention to various layers of interaction between the operator, machine, and control systems. Let’s break down each layer more closely.

a. Monitoring Operator Signals

Gathers physiological data (like heart rate, body temperature, and fatigue).

Wearable tech (think smartwatches or helmets) feeds this data into the Operator Digital Twin (DT).

This creates health-aware automation, where decision-making considers human well-being.

b. Operator Digital Twin (DT)

Reflects the operator’s current state, incorporating physical and cognitive data.

Keeps a continuous line of communication with the control room and machine DT.

Supports training simulations and adjusts workloads based on the operator’s condition.

c. Control Room

Acts as the central node for: * Planning * Configuration * Monitoring * Decision-making * Human-to-machine interaction

Enables two-way data exchange among operators, machine DTs, and field systems.

Uses AI for predictive maintenance, anomaly detection, and improving processes.

d. Machine Digital Twin (DT)

Reflects the machine’s state (like temperature, vibration, throughput, energy consumption, etc.).

Ensures state synchronization between physical and virtual entities.

Offers a testing ground for training, troubleshooting, and tuning performance without disrupting ongoing production.

e. Telemetry and Control

Handles data exchange between physical machines, their digital twins, and the control room.

Guarantees real-time telemetry, feedback loops, and fault detection.

f. Direct Sync & Control

Enables direct communication between the machine DT and the physical system for quick control actions.

Especially crucial for time-sensitive tasks like coordinating robotics and automating industrial processes.

Augmented Perception and Human Interaction

The diagram also highlights Augmented Perception & Interaction, where operators utilize AR/VR devices or smart wearables to visualize digital data in real-world settings.

This facilitates:

Immersive training: Operators can practice on virtual models without risking actual operations.

Situational awareness: Real-time overlays can indicate equipment status, safety alerts, and process data.

Guided maintenance: AR devices can project repair instructions right onto machines.

These human-augmented systems boost both safety and efficiency by mixing human intuition with machine accuracy.

The Importance of Telecommunication Networks

Telecom technologies, especially 5G and edge computing, are vital for making this architecture work.

a. Low Latency and High Reliability

Real-time syncing of physical and digital twins demands millisecond-level latency.

5G URLLC (Ultra-Reliable Low-Latency Communication) ensures consistent feedback loops.

b. Edge and Cloud Integration

Edge computing processes time-sensitive data closer to the operator or machine.

Cloud systems take care of analytics, long-term storage, and predictive modeling.

c. Network Slicing

Creates dedicated communication channels for various industrial processes.

Guarantees a steady QoS (Quality of Service) for control and telemetry.

These features position 5G and modern telecom networks as the connective framework of the human-machine ecosystem.

Examples of Operator-Machine Collaboration

The combination of DTs, AI, and telecom networks is transforming several industrial fields:

Industry Application Benefits Manufacturing Supervising machines in real-time & predictive maintenance Decreased downtime, improved yields Energy Remote turbine and grid management Safer operations, optimized load handling Healthcare Monitoring operator fatigue Fewer mistakes, better patient outcomes Mining AR-assisted remote operation of machines Increased safety and precision Logistics Automated sorting with human oversight Faster processing, more flexible routing

Each of these scenarios taps into Digital Twins and telemetry-driven feedback loops to enhance cooperation between people and intelligent systems.

Advantages of Digital Twin–Based Collaboration

Bringing together operators and machines through DTs offers several operational benefits:

a. Better Safety

Continuous monitoring of operator health and environmental conditions helps prevent accidents related to fatigue.

b. Real-Time Training

Operators can practice using virtual models, simulating complex situations without any production risk.

c. Boosted Productivity

Predictive insights facilitate proactive maintenance and resource management, reducing downtime.

d. Informed Decision-Making

DTs provide context-specific intelligence, leading to quicker and more informed reactions to any system issues.

e. Human-Focused Automation

This approach keeps a balance between automation and human judgment, fostering resilient and adaptive operations.

Challenges and Future Directions

Even with its potential, DT-based industrial collaboration encounters significant hurdles:

Data interoperability: Getting different vendors' systems and old gear to work together.

Cybersecurity: Safeguarding DTs and operator information from cyber threats.

Scalability: Keeping track of thousands of synchronized digital models in real time.

Human factors: Crafting intuitive interfaces that support human understanding without overwhelming them.

Future developments will likely emphasize:

AI-driven adaptive twins that adjust based on behavioral shifts.

Cognitive DTs that can gauge operator emotions and stress levels.

6G-enabled ultra-low latency connections for more realistic interactions.

Wrapping Up

The blend of Digital Twins, telemetry, and augmented human interfaces represents a significant leap towards Industry 5.0—where humans and machines work together symbiotically.

The architecture shown in the diagram clearly illustrates this next-gen ecosystem. By linking operators and machines through real-time data, AI, and advanced networks, industries can reach new heights in safety, efficiency, and intelligence.

Ultimately, Digital Twins transform manufacturing from automated settings to collaborative, adaptive ecosystems, keeping humans at the core—empowered by technology instead of being replaced by it.