Industrial Internet of Things (IIoT): Architecture, Layers, and Standards for Smart Manufacturing

Industrial Internet of Things (IIoT): The Future of Industrial Connectivity The Industrial Internet of Things (IIoT) is changing the game in modern manufacturing by linking up machines, sensors, and control systems via smart, data-driven networks. This setup allows for real-time monitoring, predictive analytics, and improved efficiency across complex industrial systems.

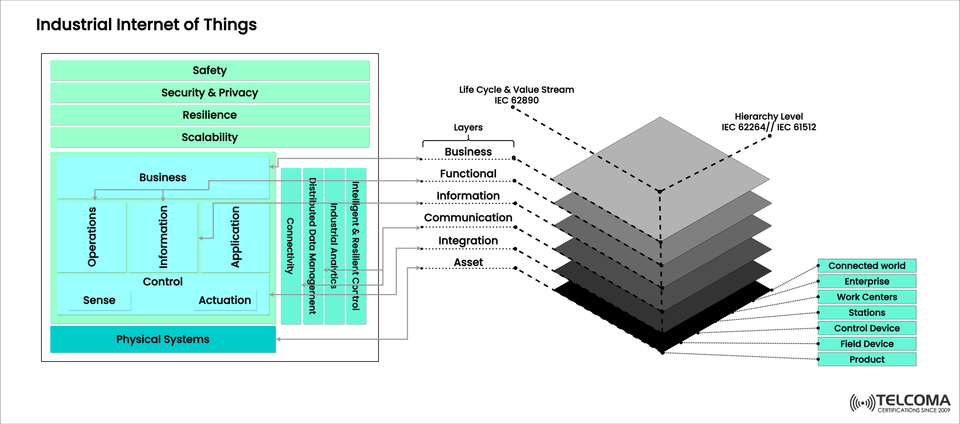

The image shared by Telcoma gives a clear visual of the IIoT reference architecture, highlighting its layered design, communication norms, and structure as laid out by IEC 62264, IEC 61512, and IEC 62890. These standards work together to make sure that industrial systems are interoperable, scalable, and resilient for their entire lifecycle.

- What’s the Industrial Internet of Things (IIoT)? The IIoT is basically extending traditional IoT ideas into industrial areas like manufacturing, energy, logistics, and utilities. Unlike consumer IoT, which is all about making life easier and more convenient, IIoT focuses on automation, data integrity, safety, and real-time control.

In a nutshell, IIoT creates a networked ecosystem where:

Machines and sensors gather data from physical systems.

Communication layers securely transmit that data.

Analytics and AI turn the data into useful insights.

Business applications use these insights to boost performance and productivity.

This transformation is central to Industry 4.0, giving rise to smart factories and cyber-physical systems that can adapt on their own to changes in production and demand.

- An Overview of IIoT Architecture The architecture depicted in the diagram breaks IIoT down into six key layers, aligning with the IEC 62264/61512 hierarchy levels and IEC 62890 lifecycle stages.

IIoT Layers and Their Functions:

Layer Function Example Components

Asset Layer Represents physical devices and sensors.

Field devices, robots, PLCs, actuators

Integration LayerLinks and harmonizes data from various sources.

Gateways, middleware, IoT hubs

Communication LayerEnsures secure, real-time data exchange.

5G networks, Ethernet, MQTT, OPC-UA

Information LayerProcesses and keeps data for analysis.

Databases, edge computing nodes

Functional LayerBrings intelligence through analytics and AI.

Predictive models, digital twins

Business LayerTurns operational insights into business strategies.

ERP, MES, enterprise dashboards

Every layer plays a role in creating a smooth flow of information — starting from sensor data at the ground level to decision-making at the business level.

- The Hierarchy of Industrial Systems The right side of the diagram outlines the industrial hierarchy, linking IIoT layers to operational levels defined by IEC 62264/61512.

Hierarchy Levels:

Product: The physical item or unit being made.

Field Device: Sensors and actuators that connect directly to machines.

Control Device: PLCs, RTUs, or controllers that handle process logic.

Station: Specific operational units (like assembly line cells).

Work Centers: Groups of multiple stations.

Enterprise: Centralized management and resource strategy.

Connected World: Ties in with outside systems, cloud services, and global data platforms.

This hierarchy guarantees vertical integration — connecting operations at the field level with top-tier business systems for a complete view and control.

Main Functional Areas of IIoT The left side of the image highlights essential IIoT functional areas and how they connect.

a. Physical Systems This is the base of IIoT — the real-world assets like machines, tools, and robots set up with sensors for data sensing and actuation.

Sense: Captures environmental and process information.

Actuation: Carries out control commands based on analytics.

b. Control This connects sensing and actuation, managing real-time feedback loops to ensure stability and accuracy.

c. Operations This includes tasks like process scheduling, maintenance, and quality control, all improved through data insights.

d. Information This layer organizes and clarifies raw data into useful information for the upper levels to use.

e. Application This hosts software systems such as MES, SCADA, and digital twins for monitoring and decision-making purposes.

f. Business This connects industrial operations with enterprise functions like finance, logistics, and customer relations.

Essential Technologies and Enablers The diagram also points out several key pillars that are crucial for a solid IIoT ecosystem:

Connectivity Reliable connectivity is the backbone of IIoT, making sure there’s continuous communication between sensors, devices, and cloud systems.

5G networks provide extremely low latency.

Protocols such as Ethernet/IP, OPC-UA, MQTT, and Modbus ensure compatibility across different systems.

Distributed Data Management Data is gathered and processed at various points — from edge computing nodes to cloud platforms, allowing for scalable and low-latency analytics.

Industrial Analytics Advanced analytics pull insights from raw data, helping with things like spotting anomalies, predicting maintenance needs, and fine-tuning processes.

Smart & Resilient Control Adaptive control systems use AI and machine learning to respond flexibly to changing industrial conditions, ensuring operations stay resilient.

Key Enablers:

5G Ultra-Reliable Low-Latency Communications (URLLC): Supports crucial control tasks.

Edge Computing: Brings processing power closer to where the data is generated.

Network Slicing: Creates dedicated segments of the network for industrial use.

Time-Sensitive Networking (TSN): Ensures precise communication for effective industrial control.

Together, these technologies make sure IIoT networks can meet the strict needs of industrial automation, safety, and synchronization.

Advantages of IIoT Architecture Putting a layered IIoT architecture into action brings clear business and operational benefits:

Boosted Productivity: Real-time insights help cut downtime and ramp up throughput.

Predictive Maintenance: AI models can catch failures before they happen.

Transparency in Operations: Smooth data flow across departments ensures clear visibility.

Energy Efficiency: Ongoing monitoring enhances resource management.

Compatibility: Standardized communications allow for vendor-agnostic integration.

Faster Decision-Making: Data-driven insights help industries respond quickly.

Challenges and Things to Consider While IIoT brings a lot of transformative benefits, there are challenges industries need to tackle:

Integrating Legacy Systems: Older equipment might not have the ability to connect digitally.

Cybersecurity Threats: More connectivity means more potential entry points for attacks.

Handling Data Overload: Managing vast amounts of data needs scalable systems.

Compliance with Standards: Following IEC, ISO, and NIST standards is absolutely necessary.

Upskilling the Workforce: Operators will need to gain digital skills and familiarize themselves with AI.

Addressing these challenges involves a strategic plan that combines telecom advancements, cybersecurity measures, and collaborative efforts across domains.

Conclusion

The Industrial Internet of Things signifies the merging of connectivity, intelligence, and automation throughout the industrial landscape. As seen in the Telcoma diagram, the layered IIoT architecture brings together physical systems, communication frameworks, analytics, and business intelligence under standardized governance (IEC 62264, IEC 61512, IEC 62890). For telecom professionals, IIoT offers a wealth of opportunities — from enabling ultra-reliable connections to fostering smart manufacturing ecosystems. By connecting operational technology (OT) with information technology (IT), IIoT is paving the way for a hyper-connected, data-driven industrial future.