Onsite MEC in Large Enterprises: Architecture, Benefits, and Use Cases

The Rise of Onsite MEC for Enterprises

As we move into Industry 4.0, businesses need real-time connectivity for automation, robotics, and IoT applications. Traditional cloud computing can be pretty powerful, but it often doesn't cut it when it comes to the ultra-low latency and data privacy requirements of critical enterprise operations.

That's where Onsite Multi-access Edge Computing (MEC) steps in. By placing MEC nodes right on the enterprise campus, companies can process data locally, seamlessly connect with 5G networks, and achieve quick responsiveness.

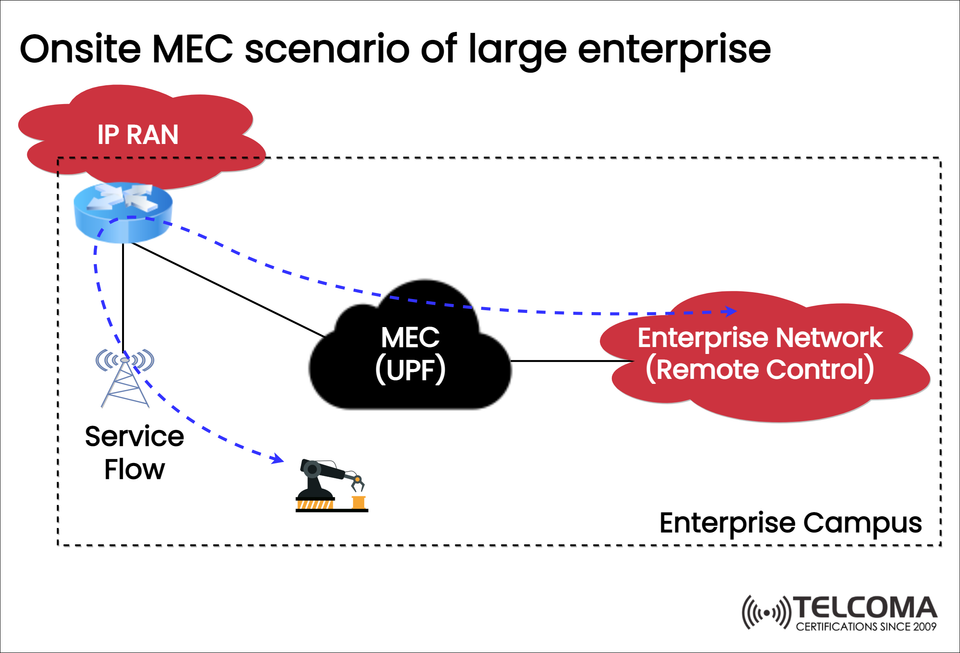

The diagram included shows a typical onsite MEC setup for large companies, illustrating how MEC connects with IP RAN, enterprise networks, remote control systems, and service flows (e.g., robotic arms in factories).

What is Onsite MEC?

Onsite MEC means putting MEC infrastructure right within the enterprise premises, instead of just relying on centralized carriers or third-party cloud services.

In this configuration:

MEC with UPF (User Plane Function): It manages the local breakout of data traffic, so it doesn't have to go all the way to the core network or an external cloud before processing.

IP RAN (Radio Access Network): This connects enterprise devices (like robots, IoT sensors, and machinery) to the MEC infrastructure.

Enterprise Network (Remote Control): It enables centralized monitoring and management of industrial processes while ensuring security and reliability.

Service Flow: This represents the real-time communication between devices and applications (for instance, controlling a robotic arm).

How the Onsite MEC Scenario Works

The diagram outlines a service flow from enterprise devices to the MEC UPF, ensuring quick connectivity.

Let's break it down step by step:

Device Communication: * Enterprise devices (like robotic arms, IoT sensors, or automated guided vehicles) generate data. * This data is sent over the IP RAN to the onsite MEC.

MEC UPF Local Breakout: * The MEC UPF processes data locally instead of routing it to a central core. * Critical decisions, like stopping a robotic arm or controlling machinery, happen in real time.

Enterprise Network Integration: * The MEC works with the enterprise network (remote control systems) for centralized monitoring and analytics. * Businesses get both low-latency local control and remote oversight.

Service Flow Continuity: * Service flows stay inside the enterprise campus boundary, ensuring low latency, high security, and compliance.

Key Benefits of Onsite MEC for Enterprises

Setting up onsite MEC nodes brings a bunch of perks, especially for big companies in manufacturing, logistics, healthcare, and energy sectors.

- Ultra-Low Latency

Processing happens right within the enterprise campus.

Enables real-time control of robotics, automated systems, and crucial IoT.

- Data Privacy and Security

Sensitive enterprise data stays onsite, cutting down risks of external exposure.

Meets compliance requirements for sectors like healthcare and finance.

- Reliable Remote Control

Businesses can bring in remote monitoring and management systems with MEC for resilience.

Even if external connections go down, local MEC keeps things running smoothly.

- Reduced Bandwidth Costs

Local processing cuts down backhaul traffic to central clouds.

Frees up network capacity for other key enterprise operations.

- Industry 4.0 Enablement

Supports automation, AI-driven manufacturing, predictive maintenance, and AR/VR training systems.

Enterprise Use Cases of Onsite MEC

Onsite MEC isn’t just for one sector—it’s useful across various industries where latency and reliability are crucial.

- Smart Manufacturing

Robotic arms controlled in real-time through MEC UPF.

Monitoring production lines remotely with minimal delay.

- Healthcare and Remote Surgery

Onsite MEC ensures seamless communication between medical devices and monitoring systems.

Facilitates AR-assisted surgeries within hospital campuses.

- Logistics and Warehousing

Autonomous guided vehicles (AGVs) and drones rely on MEC for immediate navigation.

Enterprise networks keep an eye on fleet performance remotely.

- Energy and Utilities

Power grids and oil refineries use MEC for instant anomaly detection.

Remote control systems help maintain safety and stability in operations.

- Enterprise Private 5G Networks

Companies deploying private 5G networks integrate MEC to ensure high reliability.

Supports IoT-heavy applications without relying on public clouds.

Comparison: Onsite MEC vs Centralized Cloud

Feature Onsite MEC (Enterprise Campus)Centralized Cloud Latency Ultra-low (1–10 ms)Higher (50–100 ms)Data Privacy Localized, secure Exposed to external cloud Bandwidth Usage Optimized (local breakout)Heavy backhaul traffic Control Enterprise-managed Operator/OTT managed Reliability High (local operations continue even if WAN fails)Dependent on external connectivity

Challenges in Deploying Onsite MEC

While onsite MEC has a lot of benefits, enterprises and operators do face some bumps in the road:

High Deployment Costs: Setting up MEC infrastructure at enterprise campuses needs a good bit of upfront investment.

Complex Orchestration: Juggling MEC with enterprise IT systems can get tricky.

Standardization Issues: Getting different vendors' hardware and software to work together requires a certain level of interoperability.

Skilled Workforce: Enterprises need telecom-savvy people to manage MEC-based private 5G setups.

Why Enterprises Should Invest in Onsite MEC

Even with the challenges, onsite MEC is quickly becoming a cornerstone of enterprise digital transformation. As industries shift towards automation and IoT-rich ecosystems, MEC allows for:

Quicker decision-making

Consistent service continuity

Lower operational risks

Cost-efficient handling of data

For large businesses looking for a competitive edge in Industry 4.0, onsite MEC has turned from a nice-to-have into a must-have.

Conclusion

The diagram clearly shows how Onsite MEC for large enterprises facilitates real-time communication between devices, MEC nodes, and enterprise networks—all within the secure confines of an enterprise campus.

By deploying MEC UPF onsite, enterprises can achieve ultra-low latency, secure data processing, and dependable remote control capabilities. Whether it’s smart factories, logistics hubs, hospitals, or energy grids, onsite MEC makes sure mission-critical applications run smoothly and securely.

As 5G continues to grow, onsite MEC is set to play a vital role in enterprise digital transformation, driving Industry 4.0 innovations and maximizing the potential of connected ecosystems.