Remote Access to Field Devices Through Gateways in the Industrial Automation Pyramid

Remote Access to Field Devices Using Gateways in the Automation Pyramid

Industrial automation is really at the heart of today's manufacturing landscape, driving everything from automotive assembly lines to smart factories. But getting access to and controlling field devices—like sensors, actuators, and drives—across the different layers of an enterprise network, especially when you need to connect from a distance, can be tricky.

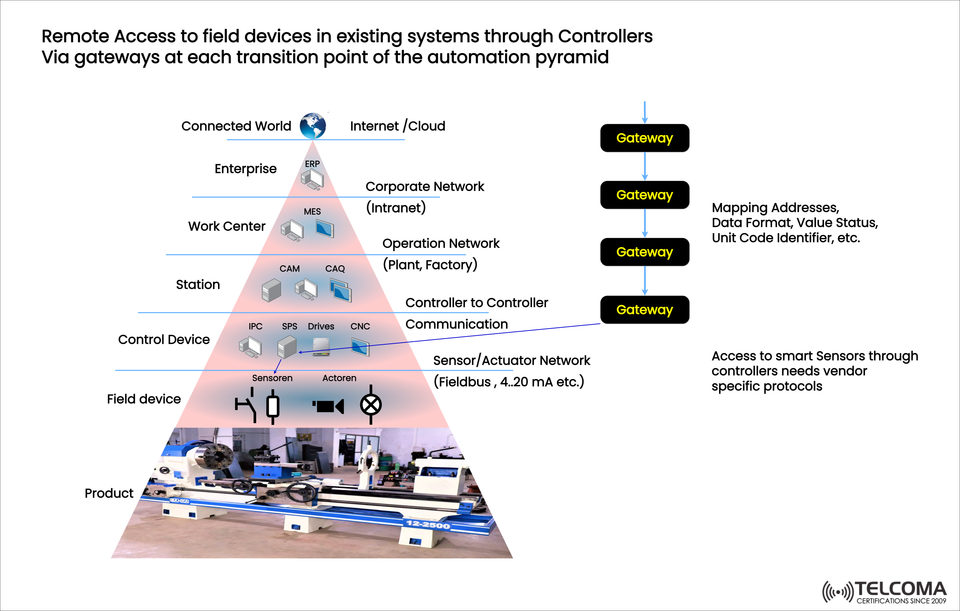

The image included shows a pyramid architecture for industrial automation. It highlights how gateways at each level facilitate smooth communication from field devices all the way up to the enterprise network and cloud. This layered setup allows engineers to keep an eye on, manage, and improve operations safely and effectively.

In this article, we’ll dive into the automation pyramid, explore the role of gateways, and look at how this setup supports remote access, data interoperability, and IIoT integration.

Understanding the Automation Pyramid

The automation pyramid is a conceptual framework that illustrates the hierarchy of devices, systems, and networks within an industrial plant. Each layer has specific roles and interacts with both the layers above and below it.

Key layers you can see in the image:

Layer / Examples / Components / Function

Physical equipment on the shop floor / Final manufactured product

Field Device Layer / Sensors (temperature, pressure), actuators (valves, motors) / Measure physical variables and execute actions

Control Device Layer / PLCs, IPCs, Drives, CNC controllers / Execute control logic, interact with field devices

Station Layer / CAM, CAQ systems / Coordinate workstations and quality control

Work Center Layer / MES (Manufacturing Execution System) / Schedule production, collect data

Enterprise Layer / ERP systems / Business management, planning, analytics

Connected World / Internet / Cloud / Global connectivity, remote monitoring

This hierarchy ensures a structured flow of data, starting from real-time process variables at the bottom and leading up to business intelligence and decision-making at the top.

The Role of Gateways in Remote Access

At each transition point in the pyramid, gateways serve as bridges between different networks, communication protocols, and data models.

Key Functions of Gateways

Protocol Conversion: They convert fieldbus, Modbus, or proprietary controller data into IP-based formats.

Data Mapping: They translate addresses, data formats, and unit identifiers into standardized structures for higher layers.

Security & Authentication: These gateways secure communication when exposing field devices to outside networks.

Edge Processing: They carry out local computations (like filtering and aggregation) to lessen upstream bandwidth use.

Remote Access Enablement: They provide authorized users the ability to monitor or control field devices from distant locations or cloud platforms.

Gateways at Each Level of the Automation Pyramid

- Field Device to Control Device Gateway

Function: Connects sensors and actuators to controllers like PLCs.

Challenges: Vendor-specific protocols often necessitate custom drivers.

Use Case: Converting analog 4-20 mA signals into digital data for controllers.

- Control Device to Station Gateway

Function: Links controller data with station-level software like CAM and CAQ.

Example: Aggregating machine health data for predictive maintenance dashboards.

- Station to Work Center Gateway

Function: Gathers station-level production data and funnels it to MES for scheduling and traceability.

Benefit: Gives manufacturing managers real-time shop floor visibility.

- Work Center to Enterprise Gateway

Function: Facilitates integration with ERP systems for production planning, inventory management, and optimizing costs.

Outcome: Aligns shop floor activities with business objectives.

- Enterprise to Cloud Gateway

Function: Securely sends enterprise data to cloud services for global monitoring and analytics.

Benefit: Makes Industry 4.0 applications like remote diagnostics, AI-driven optimization, and digital twins possible.

Data Management and Interoperability

The image also points out crucial needs for mapping addresses, data formats, value statuses, and unit identifiers. This allows data moving from the field layer to the cloud to stay accurate, consistent, and meaningful.

Standardization is essential—gateways typically support OPC UA, MQTT, and REST APIs to promote interoperability among different vendor ecosystems.

Advantages of Using Gateways for Remote Access

Advantage / Explanation

Seamless Connectivity / Links otherwise isolated networks.

Legacy System Integration / Prolongs the lifespan of older controllers by making them IIoT-ready.

Secure Remote Access / Shields industrial control systems from cyber threats.

Scalable Architecture / More devices and networks can be incorporated without major redesigns.

Real-Time Monitoring / Allows for proactive maintenance and quicker troubleshooting.

Challenges in Implementing Gateways

While gateways are vital, deploying them comes with its own set of challenges:

Cybersecurity Risks: Opening up OT (Operational Technology) networks to IT or cloud systems can create vulnerabilities.

Latency Sensitivity: It’s important to keep real-time control loops intact even with added communication layers.

Complex Integration: Requires knowledge of multiple communication standards and protocols.

Vendor Lock-in: Certain gateways are closely tied to specific hardware vendors, which can limit flexibility.

Solutions involve using secure VPNs, TLS encryption, redundant gateways, and open standards (like OPC UA and MQTT) to build future-proof architectures.

Use Cases of Remote Access Gateways

Smart Factories: Monitoring machines from afar, using AI models for predictive maintenance.

Energy Management: Gathering real-time data from distributed energy assets.

Process Industries: Remote controls for valves, temperature sensors, and flow meters.

Automotive Manufacturing: Centralized oversight of CNC machines and robots across various plants.

Conclusion

Gateways are fundamental to today’s industrial automation and IIoT frameworks. By providing remote access at every level of the automation pyramid, they create a connection between operational technology (OT) and information technology (IT).

For telecom pros and industrial engineers, grasping this layered approach to gateways is crucial for crafting secure, scalable, and future-ready systems. As Industry 4.0 and edge computing continue to evolve, gateways will be even more significant—not merely as translators, but as intelligent edge nodes that can perform analytics and support autonomous decision-making.