Top Technology Enablers of Industry 5.0: How 5G, Blockchain, and AI Are Redefining the Future of Manufacturing

Technology Enablers of Industry 5.0

We're witnessing a shift from Industry 4.0—which was all about automation and connectivity—to Industry 5.0, where humans and machines work together in a smarter way. Unlike the previous phase, which focused mostly on digital transformation, Industry 5.0 emphasizes a human-centered approach, sustainability, and resilience.

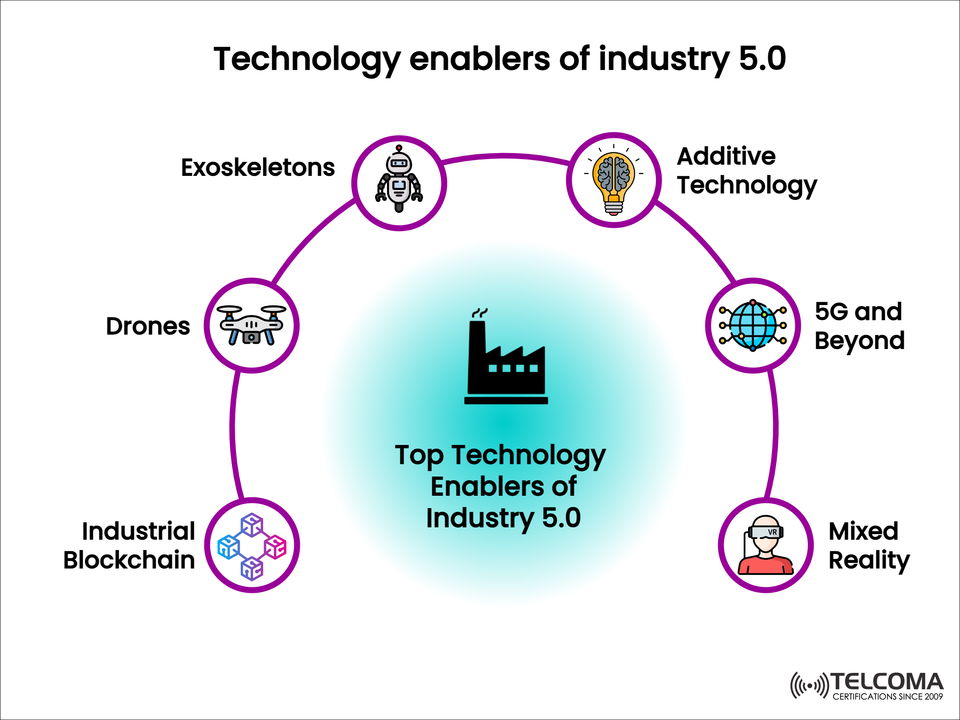

The image we've uploaded showcases the key technology enablers that are driving this fresh industrial revolution:

Industrial Blockchain

Drones

Exoskeletons

Additive Technology

5G and Beyond

Mixed Reality

Each of these technologies plays a role in making manufacturing smarter, streamlining operations, and boosting the collaboration between humans and machines. Let’s dive into how these advances are coming together to lay the groundwork for Industry 5.0.

Understanding Industry 5.0: The Human-Centric Revolution

Industry 5.0 marks the next step in the evolution of industry, highlighting the collaboration between humans and intelligent machines. The main goal here is to create production systems that are personalized, efficient, and sustainable.

Key Pillars of Industry 5.0:

Human-Machine Collaboration: It’s about mixing robotic precision with human ingenuity.

Sustainability: Leveraging technology to cut down on waste and energy use.

Resilience: Designing adaptable systems for the unpredictable global supply chain.

Personalization: Efficiently crafting custom-made products.

Digital-Physical Integration: Merging the physical and digital realms using tech like AR, VR, IoT, and AI.

Industry 5.0 isn’t meant to replace Industry 4.0; it’s an evolution that reintegrates the human element into smart manufacturing.

Industrial Blockchain: Building Trust in Smart Manufacturing

Blockchain technology serves as the foundation for secure, transparent, and decentralized data exchange within the Industry 5.0 framework.

Applications in Industry 5.0:

Supply Chain Transparency: Blockchain monitors every part from the source to production, guaranteeing authenticity and adherence to standards.

Smart Contracts: These help automate transactions among suppliers, manufacturers, and logistics.

Data Security: Safeguarding sensitive IoT and production data against tampering or cyber threats.

Sustainability Tracking: Keeping tabs on carbon footprints and recycling data to promote eco-friendly practices.

In telecom-enabled factories, blockchain facilitates real-time coordination between machines and digital twins, with 5G providing quick communication.

Example:

A telecom manufacturer can leverage blockchain to confirm that each semiconductor component is ethically sourced and rigorously tested, cutting down the risk of counterfeit parts.

Drones: Redefining Industrial Surveillance and Logistics

Drones have evolved beyond just taking aerial photos; they’re now crucial for smart manufacturing, logistics, and managing telecom infrastructure.

Industrial Applications:

Warehouse Automation: Keeping track of inventory and optimizing storage in real time.

Predictive Maintenance: Using AI-powered drones to inspect telecom towers, pipelines, and large machinery.

Supply Chain Optimization: Facilitating just-in-time delivery of components.

Emergency Response: Conducting surveillance and safety checks in risky environments.

Why It Matters for Telecom Professionals:

With 5G and ultra-low latency, drones can send high-resolution video streams and sensor data as it happens, allowing for remote control, predictive analytics, and AI-driven decision-making.

Exoskeletons: Empowering Human-Machine Collaboration

Exoskeletons perfectly embody the human-centric focus of Industry 5.0. These wearable robotic suits enhance human strength, minimize fatigue, and boost workplace safety.

Types of Exoskeletons:

Type Purpose

Passive Exoskeletons: Provide mechanical support to lessen strain on muscles and joints.

Active Exoskeletons: Use electric motors or hydraulics to increase movement and strength.

Hybrid Systems: Merge mechanical and powered assistance for added versatility.

Key Benefits:

Cuts down on workplace injuries in factories and construction sites.

Boosts worker productivity and accuracy.

Aids aging workforces by improving endurance.

With IoT sensors and 5G connectivity, exoskeletons can also send biometric and performance data to central systems for ongoing monitoring and safety analytics.

Additive Technology: Accelerating Customization and Sustainability

Additive manufacturing, more commonly known as 3D printing, is a vital part of Industry 5.0. It supports rapid prototyping, on-demand production, and waste reduction—essential goals for sustainable manufacturing.

Key Applications:

On-demand Manufacturing: Prevents overproduction and cuts down on inventory waste.

Complex Design Fabrication: Allows for intricate components that traditional methods can’t achieve.

Spare Parts and Tooling: Quickly creates customized parts for telecom, automotive, and aerospace industries.

Sustainability: Minimizes material use and carbon emissions.

5G and AI Integration:

5G networks make real-time communication possible between printers, sensors, and cloud systems, enhancing every stage of the printing process.

Example:

A telecom company could utilize 3D printing to manufacture custom antenna components or repair tools locally, slashing downtime and logistics costs.

5G and Beyond: The Backbone of Industry 5.0

The 5G network, and its future evolution into 6G, serves as the connectivity foundation for Industry 5.0. It guarantees that humans, machines, and AI systems can interact seamlessly in real time.

Key Enabling Features:

Ultra-Low Latency: Facilitates robotic precision and remote collaboration.

High Reliability: Meets the demands of mission-critical industrial applications.

Massive IoT Connectivity: Links billions of devices at once.

Network Slicing: Allocates dedicated network resources for manufacturing, healthcare, or logistics needs.

5G + AI + Edge Computing:

The combination of 5G with AI and edge computing allows for real-time decision-making right where production happens—crucial for adaptive and autonomous manufacturing.

Looking Ahead:

6G is set to enhance these capabilities, introducing AI-native networking, terahertz communication, and real-time digital twins—fuelling hyper-personalized production and predictive operations.

Mixed Reality: Transforming Training, Design, and Operations

Mixed Reality (MR)—a combination of Augmented Reality (AR) and Virtual Reality (VR)—is key to integrating the physical and digital aspects of Industry 5.0.

Use Cases in Manufacturing:

Training and Skill Development: Workers can practice in virtual settings with realistic simulations.

Design Visualization: Engineers can manipulate and visualize 3D models before production.

Remote Assistance: Technicians get live AR support from remote experts during maintenance tasks.

Customer Personalization: Allows customers to interactively experience and modify product designs.

The Telecom Edge:

Telecom networks offer the bandwidth and low latency necessary for smooth mixed reality experiences. Thanks to 5G, MR applications can stream 3D holographic visuals live, paving the way for practical remote collaboration.

The Convergence of Technologies in Industry 5.0

Industry 5.0 flourishes on interconnected technologies rather than isolated innovations. The real change occurs when these enablers collaborate:

Technology Synergistic Role

5G: Powers real-time communication and automation

Blockchain: Secures and verifies industrial data

Drones: Adds mobility and ongoing surveillance

Exoskeletons: Boosts human physical abilities

Additive Technology: Encourages flexible, sustainable production

Mixed Reality: Links digital and human intelligence

Together, these technologies create the digital nervous system of Industry 5.0—responsive, intelligent, and highly cooperative.

Conclusion: A Human-Centric Future Powered by Technology

Industry 5.0 is reshaping how humans and technology interact. It’s not just about replacing people with machines; it’s about enhancing human capabilities through intelligent machines, sustainable practices, and connected systems.

For those in the telecom world, this future hinges on 5G, AI, and blockchain-powered networks, laying the groundwork for the next industrial revolution.

As we move forward, the success of Industry 5.0 will hinge on whether we can effectively merge human creativity with digital smarts—crafting factories that are not only intelligent but also empathetic, efficient, and sustainable.